Fodder silos are designed for feed and bran warehousing. They are necessary on livestock farms as well as swine and poultry farms. Michał silos are made from high quality steel with zinc covering. Appropriate thickness of sheet metal together with solid structure make silos durable.

| Model | H514/4 | H514/8 | H514/5 | H514 | H514/1 | H514/2 | H514/3 | H514/6 | H514/7 |

| Capacity [m3] | 4,69 | 5,67 | 7,87 | 12,48 | 19,65 | 26,81 | 33,98 | 41,15 | 48,32 |

| Feed amount (0,65t/m3)[t] * | 3,1 | 3,68 | 5,1 | 8,1 | 12,8 | 17,4 | 22,0 | 26,7 | 31,1 |

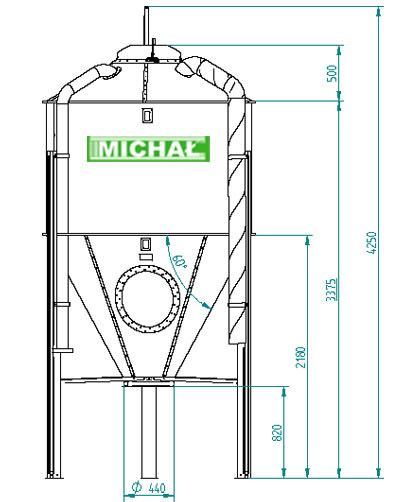

| Diameter D [mm] | 1847 | 2022 | 1847 | 2770 | 2770 | 2770 | 2770 | 2770 | 2770 |

| Total height H2 [mm] | 4250 | 4248 | 5270 | 5350 | 6540 | 7730 | 8920 | 10110 | 11300 |

| Outlet height [mm] | 820 | 700 | 650 | 700 | 700 | 700 | 700 | 700 | 700 |

| Outlet diameter [mm] | 440 | 440 | 440 | 440 | 440 | 440 | 440 | 440 | 440 |

| Weight [kg] | 260 | 300 | 340 | 520 | 640 | 940 | 1230 | 1490 | 1750 |

* approximate capacity for the feed (only for pneumatic loading)

Silos „MICHAL” model H514/4, H 514/8, H514/5 are set up on 3 legs; silos H514 and H514/1 on 4 legs; all the other silos are set up on 6 legs. Silo legs are made from steel with zinc covering which, makes them more resistant to corrosion than legs with paint coat.

Silos „MICHAL” model H514/4, H 514/8, H514/5 are set up on 3 legs; silos H514 and H514/1 on 4 legs; all the other silos are set up on 6 legs. Silo legs are made from steel with zinc covering which, makes them more resistant to corrosion than legs with paint coat.

The loading of a silo may be done through a loading pipe which is ended with a fast action lock.A special cover which can be opened manually and which gives alternative ways of loading is a standard equipment of feed silos.Appropriate cone gradient as well as outflow opening (O 440) ensures easy flow of feed into transportation system.

A side outlet in a cone (which is an extra equimpent) helps to collect fodder.

+48 86 275 01 46

+48 86 275 01 46